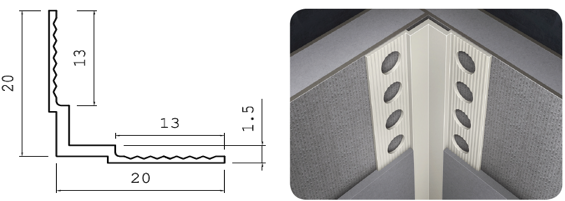

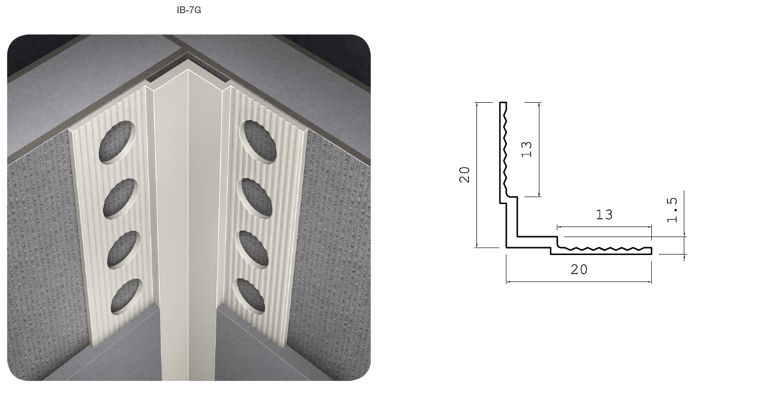

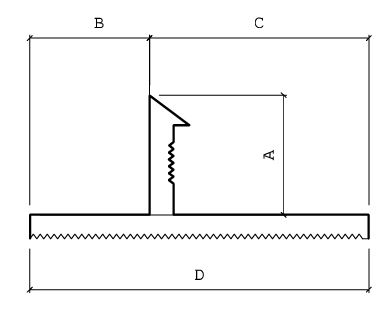

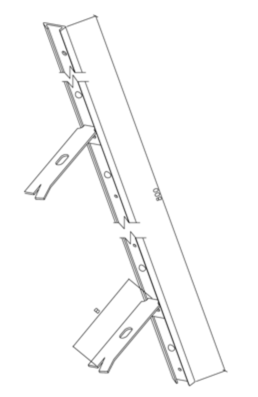

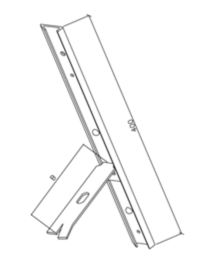

CORNER BEAD reinforces exterior stucco or plaster corners with durable, straight and rust free vinyl corners. Our vinyl corner bead is specially manufactured with striation and perforation along the flanges, which provides positive bonding when they are attached, and of stucco to the product. It becomes part of the building structure and moves along with the walls, but does not freely express its coefficient of expansion or contraction.

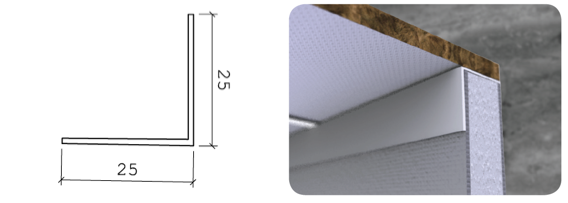

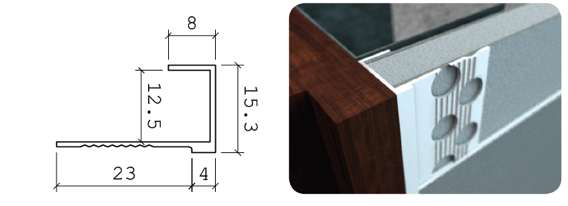

Corner beads are available in 3 main versions: sharp edge for fine corners, smooth edge, and bull-nose edge for soft corners.

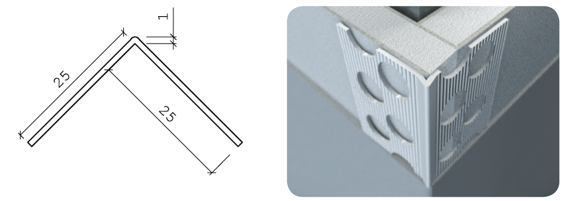

The CRL series corner bead can perform multiple functions, with adjustment for angles constrained by narrow corners, walls with acute and obtuse angles and curves for most construction radius.

Corner beads are available in 3 main versions: sharp edge for fine corners, smooth edge, and bull-nose edge for soft corners.

The CRL series corner bead can perform multiple functions, with adjustment for angles constrained by narrow corners, walls with acute and obtuse angles and curves for most construction radius.

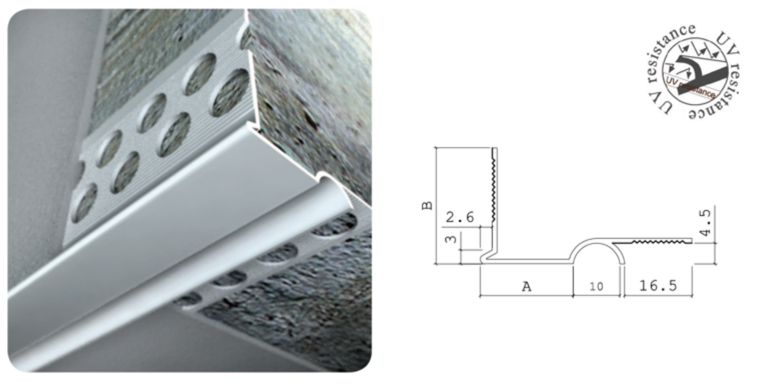

CORNER BEAD reinforces exterior stucco or plaster corners with durable, straight and rust free vinyl corners. Our vinyl corner bead is specially manufactured with striation and perforation along the flanges, which provides positive bonding when they are attached, and of stucco to the product. It becomes part of the building structure and moves along with the walls, but does not freely express its coefficient of expansion or contraction.

Corner beads are available in 3 main versions: sharp edge for fine corners, smooth edge, and bull-nose edge for soft corners.

The CRL series corner bead can perform multiple functions, with adjustment for angles constrained by narrow corners, walls with acute and obtuse angles and curves for most construction radius.

Corner beads are available in 3 main versions: sharp edge for fine corners, smooth edge, and bull-nose edge for soft corners.

The CRL series corner bead can perform multiple functions, with adjustment for angles constrained by narrow corners, walls with acute and obtuse angles and curves for most construction radius.

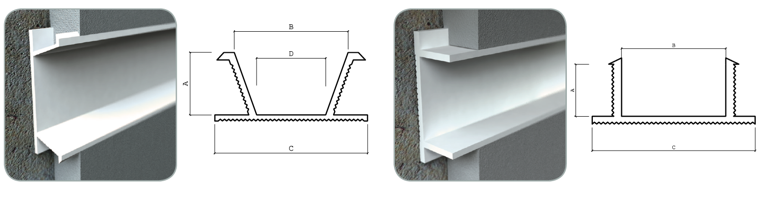

| Description | A | B | C |

|---|---|---|---|

| CRV-1 | 1 | 20 | 20 |

| CRV-2 | 2 | 25 | 20 |

| CRV-3 | 3 | 20 | 20 |

| CRV-3s | 4 | 15 | 28 |

| CRV-4 | 4 | 20 | 20 |

| CRV-4s | 5 | 20 | 20 |

| CRV-10 | 10 | 18 | 18 |

| Technical Specification | Drip Line |

|---|---|

| Mean Tensile Strength (MPa) | 27.2 |

| Mean Flexural Strength @ 5% Strain (MPa) | 66.8 |

| Mean Deflection Temperature (°C) | 60.1 |

| Mean Vicat Softening Temperature (°C) | 80.9 |

| Chemical Resistance | No colour changed and visual defects |

| Length | |

|---|---|

| CRV-1 G/W/R | 2.0m |

| CRV-2 G/W/R | 2.2m |

| CRV-3G/W/R | 2.2m |

| CRV-3s G/W/R | 2.0m |

| CRV-4 G/W/R | 2.0m |

| CRV-4s G/W/R | 2.0m |

| CRV-10 G/W/R | 2.0m |

| CRV-2S G/W/R | 2.2m |