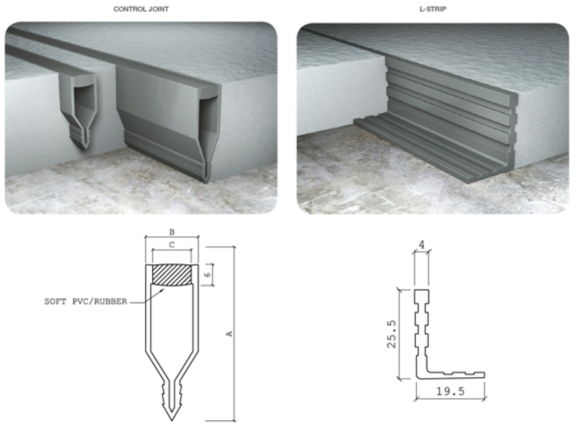

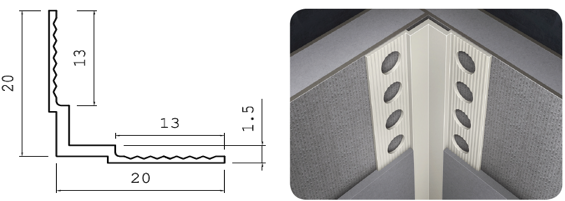

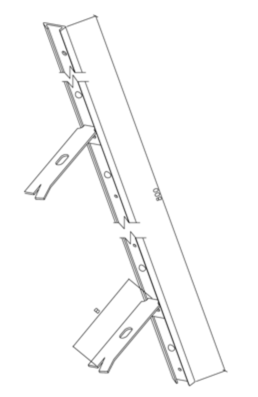

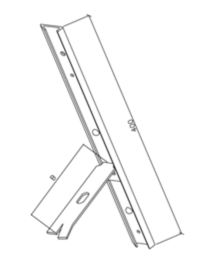

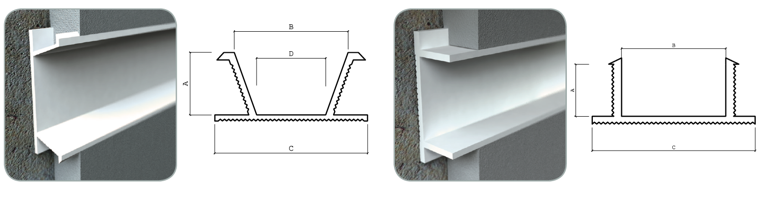

GROOVE JOINT is used to provide distinctive architecturally pleasing breaks on any stucco wall surface. Chamfered and vaulted reveals are an improvement over standard U shaped stucco reveals. Not only does this give a more appealing look to the design, it also improves the mechanism for stucco embedding and enhances the bond between the stucco and joints to reduce separation at these locations.

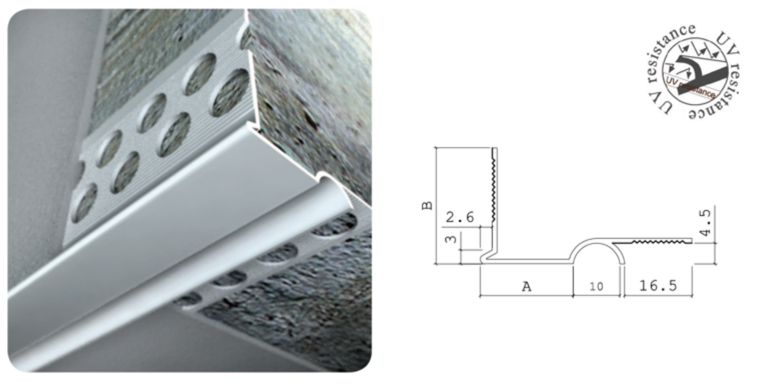

Since Groove Joints are normally used in areas which are exposed directly to sunlight, we have added Benzotriazole, an ultra violet (UV) resistant chemical additive that gives protection from discolouration.

Since Groove Joints are normally used in areas which are exposed directly to sunlight, we have added Benzotriazole, an ultra violet (UV) resistant chemical additive that gives protection from discolouration.

GROOVE JOINT is used to provide distinctive architecturally pleasing breaks on any stucco wall surface. Chamfered and vaulted reveals are an improvement over standard U shaped stucco reveals. Not only does this give a more appealing look to the design, it also improves the mechanism for stucco embedding and enhances the bond between the stucco and joints to reduce separation at these locations.

Since Groove Joints are normally used in areas which are exposed directly to sunlight, we have added Benzotriazole, an ultra violet (UV) resistant chemical additive that gives protection from discolouration.

Since Groove Joints are normally used in areas which are exposed directly to sunlight, we have added Benzotriazole, an ultra violet (UV) resistant chemical additive that gives protection from discolouration.

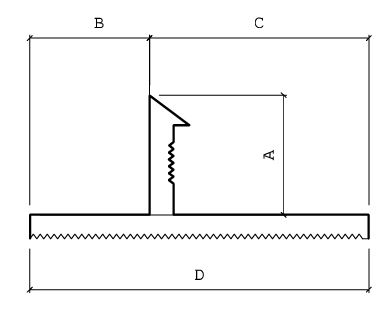

| GV – Series | A | B | C | D |

|---|---|---|---|---|

| GV-10 | 6 | 10 | 14 | 4 |

| GV-15 | 10 | 15 | 19 | 5 |

| GV-20 | 10 | 20 | 25 | 11 |

| GV-30 | 10 | 30 | 35 | 21 |

| GU – Series | A | B | C |

|---|---|---|---|

| GU-0905 | 5 | 9 | 18.5 |

| GU-1609 | 9 | 16 | 27 |

| GU-2010 | 10 | 20 | 30 |

| GU-5010 | 10 | 50 | 63 |

| Technical Specification | Groove Joint |

|---|---|

| Mean Tensile Strength (MPa) | 26.2 |

| Mean Flexural Strength @ 5% Strain (MPa) | 66.9 |

| Mean Deflection Temperature (°C) | 60.0 |

| Mean Vicat Softening Temperature (°C) | 79.5 |

| Chemical Resistance | No colour changed and visual defects |