OVERVIEW

OVERVIEW

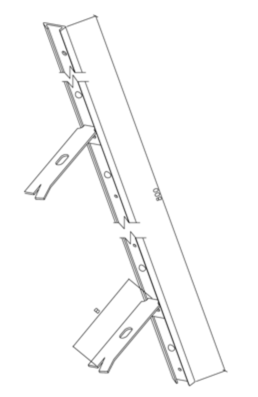

Conduit system is a closed wiring system consisting of conduits and conduit fittings for the protection and management of insulated conductors, electrical cables or communication installations, allowing them to be drawn in and/or replaced, but not to be inserted laterally. KUS provides a wide range of conduit and conduit fittings for concealed, surface wiring for electrical, Tele communication appliances for all type of projects.

Material

Calaba Electrical Rigid Conduit pipes & Accessories are manufactured from unplasticized polyvinyl chloride polymer (uPVC). The basic material of uPVC is PVC which is made from vinyl chloride monomer usually known by its initials VCM through polymerisation. Hence, it is rigid.

Conduit system is a closed wiring system consisting of conduits and conduit fittings for the protection and management of insulated conductors, electrical cables or communication installations, allowing them to be drawn in and/or replaced, but not to be inserted laterally. KUS provides a wide range of conduit and conduit fittings for concealed, surface wiring for electrical, Tele communication appliances for all type of projects.

Material Calaba KUS Electrical Rigid Conduit pipes & Accessories are manufactured from unplasticized polyvinyl chloride polymer (uPVC). The basic material of uPVC is PVC which is made from vinyl chloride monomer usually known by its initials VCM through polymerisation. Hence, it is rigid.

Codes & Compliance

| CODES | STANDARD COMPLIANCE |

| IEC 61386-21:2002 (BS EN 61386-21) | Conduit systems for cable management – Part 21: Particular requirements – Rigid conduit systems where applicable |

| BS EN 61386-22:2004+A11:2010 | Conduit systems for cable management. Particular requirements. Pliable conduit systems |

| Non-metallic conduit fittings for electrical installations. Specification for rigid conduits, fittings and boxes of insulating material where applicable” | |

| BS 4607-1:1984+A2:2010 | Non-metallic conduits and fittings for electrical installations. Specification for fittings and components of insulating material where applicable |

| BS 4662:2006+A1:2009 | Boxes for flush mounting of electrical accessories. Requirements, test methods and dimensions where applicable |

Advantages

Resistance against corrosion

uPVC material has structural flexibility that allow the material to withstand

substantial deformation without permanent distortion even in the wall, in the concrete and underground.

Resistance against corrosion

PVC is immune to damage from naturally corrosive soil conditions, as

well as electrochemical and galvanic corrosion. This ensures lower maintenance costs and superior performance

in the long run.

Fire Resistant

uPVC conduit system is inherently difficult to ignite. If the ignition source is withdrawn, it will stop

burning. Heat production is comparatively low making it particularly suitable for electrical wiring, electrical protection of

the insulated conductors and cables therein contained.

Light Weight & Efficient

uPVC can be cut, shaped, bent and joined easily in a variety of styles. Threading and special tools are not required for the installation which significantly improve the efficiency. Manual handling difficulties are also reduce due to its light weight. Thus, time and cost are saved

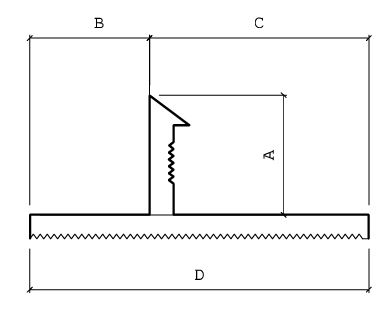

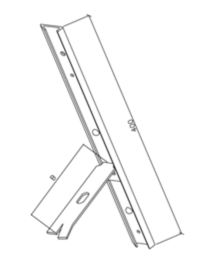

uPVC Conduits

Conduit is part of a closed wiring system of general circular cross-section for insulated conductors, electrical cables or communication installations, allowing them to be drawn in and/or replaced. It is manufactured with uPVC materical and tested accordance with IEC 61386-1 & IEC 61386 -21.

It is classified into,

- Light Duty 222112

- Medium Duty 33211

- Heavy Duty 442112

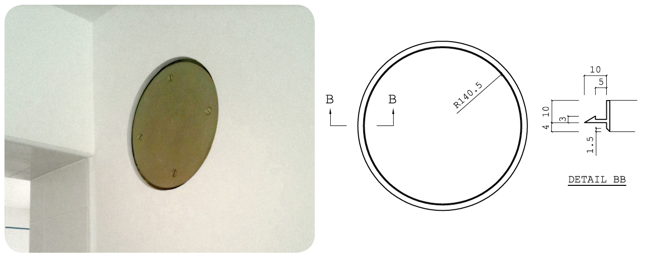

| DESCRIPTION | DIAMETER | LENGTH (M) | COLOUR |

|---|---|---|---|

| Condults | 16mm | 2.9 m | White/Black |

| 20mm | |||

| 25mm | |||

| 32mm |